Ultrasonic Machines & Other Cutting Machines

Ultrasonic Cutting Provides The Most Clean And Perfect Cut Possible With No Burnt Ends Or Fraying. Efficiently Cut Velcro, Webbing, Ribbon, and More with Automatic Ultrasonic Machinery.

Upgrade your cutting game with our cutting machinery. Our advanced automation capabilities make cutting various textile materials - including velcro, webbing, ribbon, belt loops, cords, and labels - a breeze.

Say goodbye to time-consuming manual cutting and hello to efficient and precise cuts with our non-heat process. Our machinery is designed to handle delicate fabrics and materials with care, ensuring a clean and precise cut every time.

Explore our product features and benefits to see how our cold cutting machinery can improve your textile cutting operations.

We recommend sending us samples of your material so we can run tests for you and verify the quality of cut.

-

Specialized ultrasonic label cutter with label sensor for perfect cut and accuracy each time

-

High speed : It can cut 210~220 cuts per minute.(50mm long)

(option : Max. 320 PCs /min, 50mm long)

- Accuracy : A sensor makes cut-length accurate by automatic sensing at set-position.

The anti-static brush is useful for cutting labels which generate a lot of static electricity,

preventing cutted labels from clinging to knife blade.

- Cutting type : Cutting edge is soft due to using an ultrasonic system.

- Automatic operation : It works automatically only by setting length and quantity.

- Automatic stopper : It stops automatically if materials run out during operation.

- Memory : Set-length, set-q'ty & set-speed are not erased even if power off & on.

-

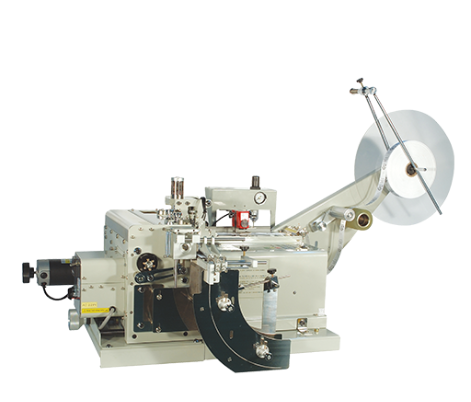

Specialized ultrasonic label cutter with label sensor and stacker for perfect cut and accuracy each time with automatic stacking

-

A sensor makes cut-length accurate by automatic sensing at set-position.

The anti-static brush is useful for cutting labels, which generate a lot of static electricity,

preventing cut labels from clinging to knife blade.

Cutting Type Cutting edge is soft due to using an ultrasonic system.

Automatic Operation It works automatically only by setting length and quantity.

Automatic Stopper It stops automatically if materials run out during operation.

Memory Function Set-length, set-q'ty & set-speed are not erased even if power off & on.

-

Specialized ultrasonic label cutter with label sensor and stacker for perfect cut and accuracy each time with automatic stacking

-

- High speed : It can cut 230 cuts(50mm long)/min. and stack at the same time.

- Accuracy : A sensor makes cut-length accurate by automatic sensing at set-position.

The anti-static brush is useful for cutting labels which generate a lot of static

electricity, preventing cut labels from clinging to knife blade.

- Cutting type : Cutting edge is soft due to using an ultrasonic system.

- Automatic operation : It works automatically only by setting length and quantity.

- Automatic stopper : It stops automatically if materials run out during operation.

- Memory : Set-length, set-q'ty & set-speed are not erased even if power off & on.

-

Specialized ultrasonic webbing cutter with pneumatic application to allow for heavy duty webbing to be cut with complete control

-

- High speed : It can cut 16~26 cuts per minute. (1m long)

- Accuracy : Cut-length is accurate owing to using a stepping motor.

- Cutting type : Because ULTRASONIC melts the end of tape, cutting is sealed neatly without

fraying. and by changing knife, you can cut webbing/ribbon in various shape and you can set

cutting time by TIMER. (0.3sec ~ )

- Automatic operation : It works automatically only by setting length and quantity.

- Automatic stopper : It stops automatically if materials run out during operation.

- Memory : Set-length, set-quantity & set-speed are not erased even if power off & on.

PRE-FEEDERS

-

Automatic winding strip tapes like labels, available to link with a printing machine, or to rewind released materials on the ground.

-

Slip-system makes the operation safe and convenient. This system also prevents the motor from being overloaded.

Standard roll weight: 1.2kg or so

Possible to adjust the winding pressure.

-

Various free-standing pre-feeders for a range of different applications.

-

Pre-feeding device to keep a constant tension of elastic band for correct length.

-

Heavy Duty Powered Automatic Roll Dispenser 25kg+

-

Model No. : TFD-250

Purpose of Use : Automatic pre-feeding device allows the material to be released in advance so that it can be cut to the correct length to maintain a constant tension.

Power Supply : AC110/220V, 50/60Hz

Packing/G.WT : 46×49×64.5cm/51.5kg

-

TR-3n can wind thread as same shape as the original bobbin, no matter how thickness of thread.

To wind sewing thread or embroidery thread separately.

-

Model No. : TR-3N

Purpose of Use : Sewing thread/embroidery thread winder

Power Supply : AC110/220V, 50/60Hz

Volume of thread

Width : 95mm

MAX. : 5,000,000mm

Winder Speed(1,380~1,680rpm)

1km : 6min. 07sec.

2km : 11min. 15sec.

3km : 15min. 35sec.

4km : 19min. 45sec.

5km : 24min. 00sec.

Machine/N.WT : 26×38×34cm/17.6kg

Packing/G.WT : 48×36×44cm/19.5kg

-

Automatic Large Bobbin Winder.

Bobbin winder, it can do 5 bobbins simultaneously in same length.

-

Model No. : TBW-05

Operating Method : belt-driven rotation

Power Supply : AC110/220V, 50[A]

Range of Length : 1~9,999m

Machine/N.WT : 74×51×74cm/40kg

Packing/G.WT : 46×49×64.5cm/51.5kg

-

TR-PL hole punch machine

-

Application - SNAP BUTTON, EYELET WORKS OF JUMPER, JACKET, JEAN, COAT, KNITWEAR, LEATHER, BELT, BAG ETC.

-It is possible to reduce the manufacturing process and manpower because the direct punching work could save the task of position marking.

-It prevents loss by accurate punching because TR-P.1 starts punching work just after pressing and possible to work, holding materials with one hand.

-TR-PL makes hole neatly due to no dancing of fabric.

-TR-PL prevents shock, noise and possible hand-injuries from hammering.

-Even a beginner can work more efficiently like a skilled workman.